Shuangkai Lighter - Pursue quality and cast high-quality goods.

Home / Advantage

Under the same working conditions, compared with the traditional hydraulic injection molding machine, it can achieve an energy-saving rate of 20%-80%.

Servo drive system, closed-loop control, compared with traditional hydraulic injection molding machine, molding repeat accuracy is greatly improved.

DKM sensitive servo drive responds quickly, and the quick start time only needs 0.05s.

the whole machine runs with low noise, and the low-speed operation is more quiet.

Compared with traditional hydraulic injection molding machines, the pressure holding time adjustment range is wider and the pressure holding performance is more stable.

The servo motor proportionally outputs hydraulic oil to avoid excess heat generation, slow heating, and hydraulic oil does not even need to be cooled, realizing significant water saving.

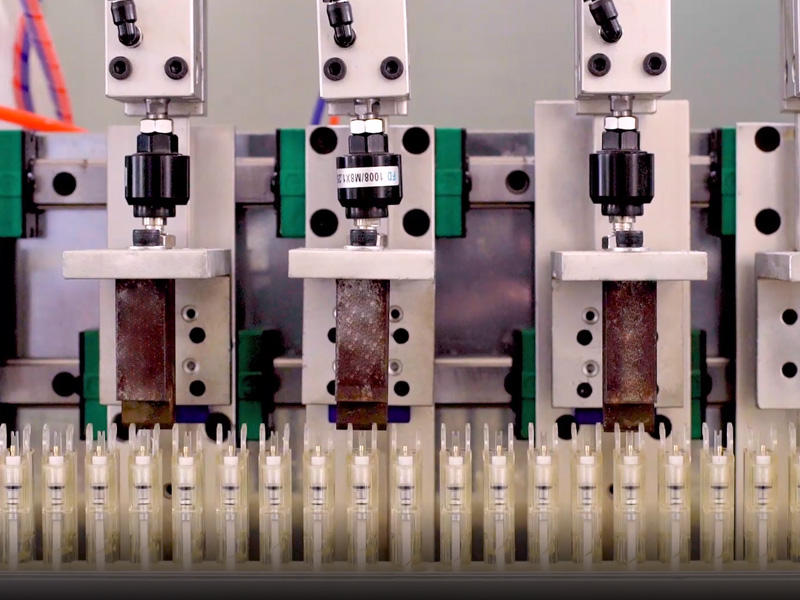

Sponge, electronics, and hardware stamping parts are purchased at designated locations, and the Shuangkai company must inspect the factory, and focus on checking whether its products meet the purchase standards of the Shuangkai company.

Specify raw materials, brands and models, and randomly inspect their purchases.

For example, the sponge sheet has many mold cavity stations and poor distribution uniformity. Only 30% of the double opening is selected.

The supplier quality communication meeting is held every half year, and personnel visit the supplier from time to time to maintain the exchange of information between the two parties and promote the improvement of product quality.

Strategic suppliers, double open to provide financial and technical support, mutual benefit, win-win, and common improvement.

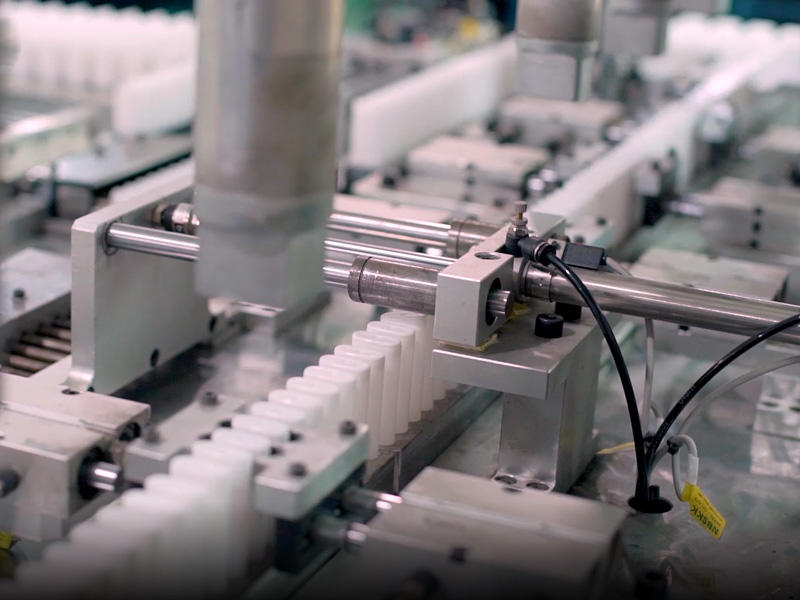

1.Advancement: Intelligent control, which can accurately move the animal material box to ensure fire detection, eliminate the complexity of the process, and realize full automation.

2.Safety: Full automation makes the operation safer and the quality is more guaranteed.

3.High efficiency: Manual adjustment of fire is about 20,000 per day, machine debugging can debug about 160,000 per day, and the production capacity is 8 times higher than that of manual.

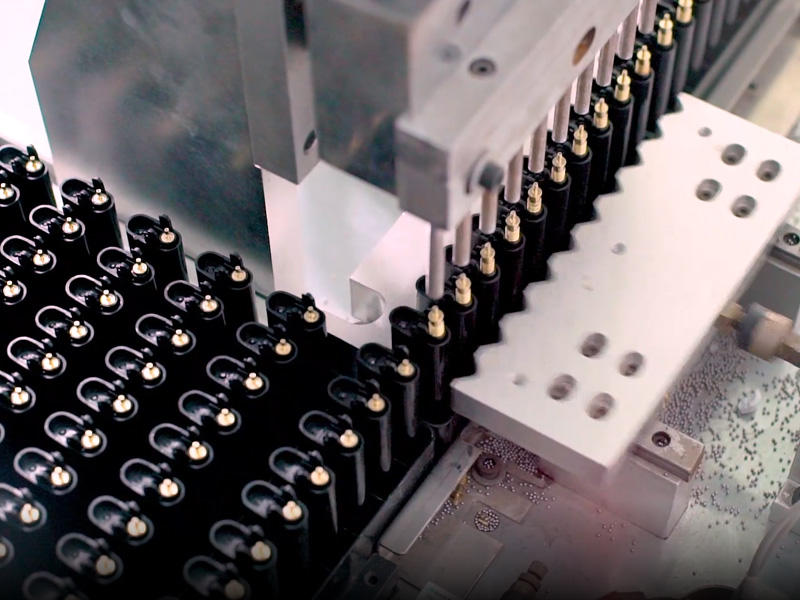

1.High-efficiency use of piracy art to improve the production capacity of the factory, the efficiency is 5 times that of manual assembly.

2.Reduce costs and improve quality.

Integrated production and sales linkage, optimized production, reasonable procurement, and careful sales.

Read More

7×24 hours hotline service: 0574-63668119 / 0574-63668115.

Read More

Regularly invite industry experts and customers to visit and guide.

Read More

Visited customers, asked customers about their usage, and solved market demand.

Read More